Lifecycle Assessment of Québec-Mined Lithium Hydroxide Monohydrate Points to Sustainable EV Battery Production

MONTREAL, QUEBEC, CANADA, September 22, 2025 /EINPresswire.com/ -- With the expansion of the electric vehicle and lithium-ion battery industries in North America come a wide range of detrimental environmental impacts, as ERA President and Concordia PhD candidate Gary Vegh has reported in the past. The mining and processing of lithium is one of the major emitters of CO2, which explains why Gary and his team at the Department of Chemical and Materials Engineering, alongside ERA Director of R&D Sarah Sajedi, have dedicated their latest research efforts to quantifying exactly which sources of emissions contribute the most.

In a rigorous 15-page paper published in the Journal of Power Sources, the authors delved into the EV battery ecosystem in Québec, Canada, to conduct a lifecycle assessment (LCA) of one ton of battery-grade lithium hydroxide monohydrate (LiOH•H2O). This compound is a critical precursor for lithium-ion batteries, has a strong profitability potential in virtue of the margin between production cost (US$ 2,900 – 6,200 per ton) and market price (US$ 8,000 – 8,500 per ton), and is reliably produced from spodumene ore mined in Québec’s deposit, one of the largest in the world. The combination of these three characteristics makes LiOH•H2O a key player in tomorrow’s North American battery industry, and thus motivates researchers in the field, like Vegh, to conduct LCAs and try to estimate the full environmental impact of its production, from raw material extraction to manufacturing, use, and disposal.

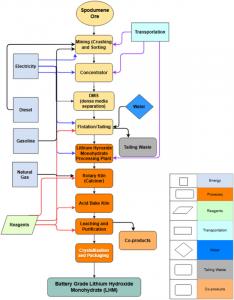

Vegh and his team gathered environmental impact assessment reports mandated by the Canadian and Québec governments and technical and feasibility reports across the mining industry to get a clear picture of the regulatory and operational context of LiOH•H2O production. They then combined this process data with background data from the Ecoinvent database and the Impact World+ Midpoint method to model the CO2-emitting processes and byproduct credits on OpenLCA.

Overall, the study found that producing a ton of LiOH•H2O from Québec spodumene emits around 5.46 tons of CO2e emissions.

The procedure is also estimated to bring about short-term and long-term climate change impacts to the tune of 5,459 kg CO2e and 5,110 kg CO2e, respectively. The inclusion of avoided byproducts lowers these values by around 19%, but water scarcity remains a big concern, as the reduced impact (which accounts for sodium sulfate recovery) is still as high as 9,422.31 m3 world-eq.

For a full breakdown of the results, you may read the open access research paper at https://www.sciencedirect.com/science/article/pii/S0378775325019858.

While the LCA may give the impression that LiOH•H2O produced from spodumene is responsible for a considerable amount of GHG emissions, the 5.46-ton value does come in significantly lower than other studies on the same topic. Using the Argonne National Laboratory GREET LCA model and transportation data exclusively from the United States, for example, yielded a value of 15.7 tons of CO2e per ton of LiOH•H2O (see reference to Kelly et al.). Even the previous LCA to base itself off Quebec spodumene and the global transportation perspective provided by Ecoinvent put the results closer to 9.66 tons of CO2e per ton of LiOH•H2O (see reference to Chordia et al.).

Vegh and his team believe differences in material inputs, provider markets, and linked production processes accounted for the variance between the LCAs, as their study is focused on the operations of a particular Québec-based mine and production facility.

Such regional specificity made it possible to identify emission hotspots relevant to the North American EV battery ecosystem. For instance, considering that energy consumption (electricity, diesel, gasoline, and natural gas), water usage, and transportation accounted for the main environmental impacts of LiOH•H2O production, the authors suggested that replacing fossil fuel vehicles with their EV counterparts and electrifying the process calciner and mining equipment (excavators, dump trucks, graders, etc.) with renewable hydroelectric power could have a disproportionate impact on CO2e emissions mitigation efforts.

The ability to leverage their results to make recommendations toward optimizing facility-wide operations proves LCAs are vital tools for the reduction of the footprint of EV batteries. Vegh calls on other researchers to apply this holistic approach and thereby find further opportunities to make the transition to electric mobility as sustainable and environmentally responsible as possible.

###

Gary Vegh

ERA Environmental Software Solutions

+1 438-802-4940

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.